UV BOYA SİSTEMLİ

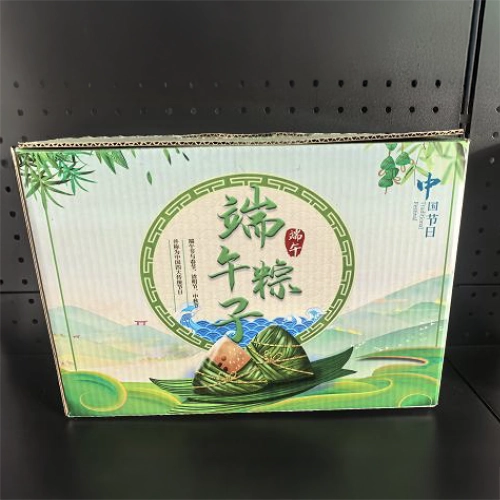

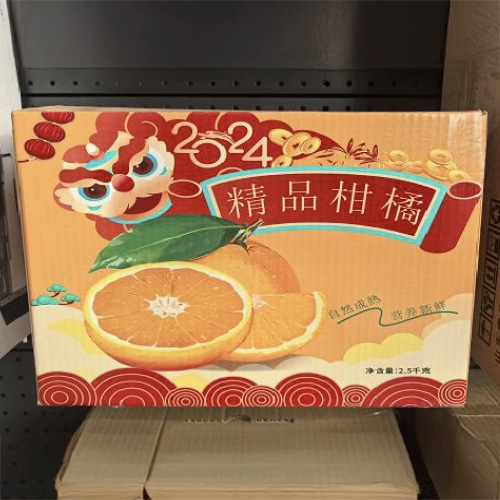

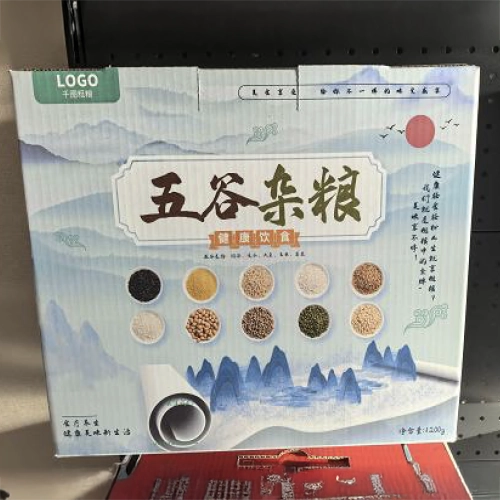

Uv Boya Sistemli Karton Ambalaj Baskı Makinesi taramalı oluklu mukavva yazıcısı, dijital mürekkep püskürtmeli baskı teknolojisini benimser. Kalıp yapımına gerek yoktur, tek parça baskı yapılabilir. Çevre dostu, su bazlı mürekkep kullanır. Maksimum baskı genişliği 2500 mm’ye kadar çıkabilir, uzunlukta herhangi bir sınır yoktur. Temel baskı çözünürlüğü 600 dpi’ye kadar ulaşır, baskı hızı ise saatte 600 metreye kadar çıkabilir. Kullanım maliyeti düşüktür, maliyet etkinliği yüksektir. Kişiye özel ve özelleştirilmiş küçük ve orta ölçekli siparişler için uygundur.

| Product Name | Scanning Corrugated Cardboard Printer |

|---|---|

| Product Model | RS2500-S-E8UV |

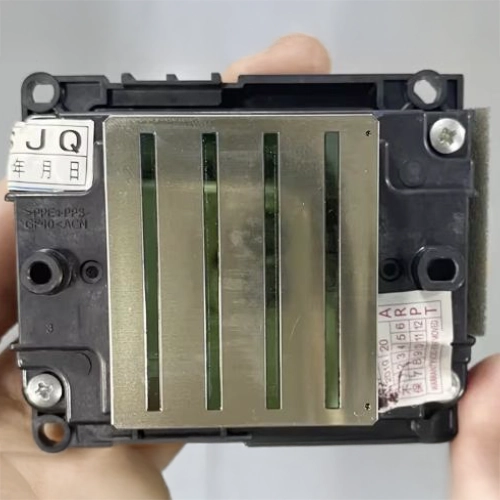

| Printhead Type | Micro piezoelectric high-precision Epson i3200 U1 printhead |

| Printhead Quantity | 8 units |

| Color Model | CMYK |

| Ink Type | UV ink |

| Printing Format | Auto feeding below 2500mm*1350mm, manual feeding 2500mm*unlimited length |

| Printing Speed | Max 400㎡/hour (Exclude feeding time) |

| Medium Distance | 2mm–4mm |

| Printing Resolution | ≥360*600dpi |

| Drying Speed | Liner-board can be dry once print out |

| Working Environment | 20–25℃ Indoor, Humidity 50–70% |

| Ink Supply | Automatic ink supply |

| Feeding Mode | Automatic leading edge feeding, default pressure roller platform, solution platform can be customized |

| Material Thickness | 3mm–40mm (or as customized) |

| Operate System | Professional RIP system, professional printing system, Win7 system with 32 bit operating system or above |

| Power Supply | About 20KW power: AC380 ±10%, 50–60HZ |

| Machine Dimension | 4920*3107*2195mm |

| Weight | 3500 KGS |

| Warranty | 12 months exclude the consumables |

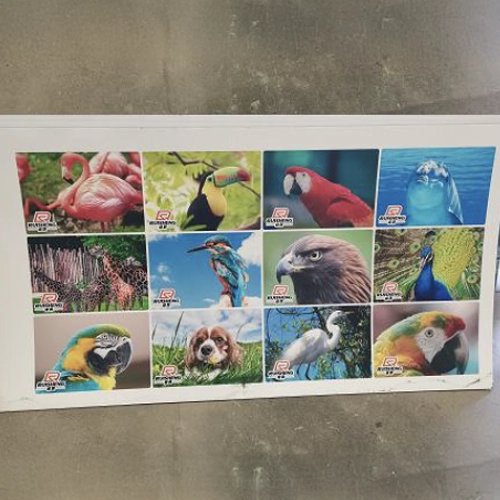

Long-lasting stable printhead, high precision, high saturation, color bright, variable ink drop technology to achieve multi-grayscale printing

The whole operation process intelligentization, no need for plate making, plate exposure and repeated color matching

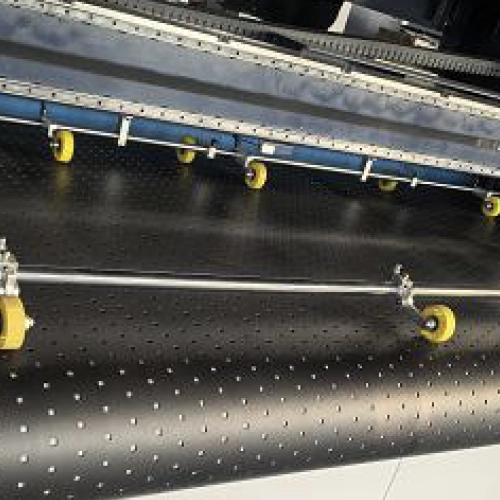

Automatic feeding with accurate positioning, less errors, lower noise and run smoothly, suit for single sheet and multi-sheet feeding

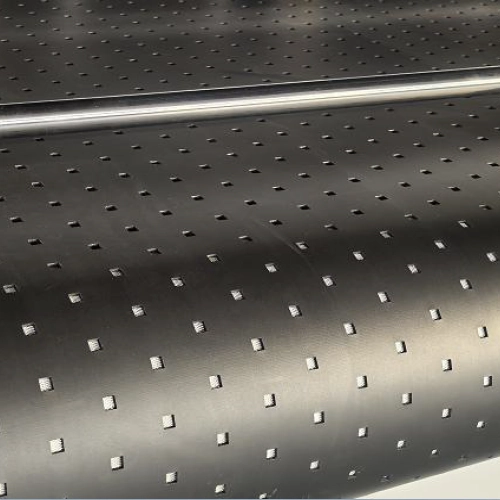

Adopt fully automatic deviation correction scheme, reasonable air suction space design, materials are firmly adsorbed

Precise positioning, achieve optimal control of stepping precision, higher precision, faster speed and more stable performance

The sun wheel pressure roller assistance to ensure the material is flat and prints well